Attrition: A primer on triage, treatment, and pre-emptive cures

June 23, 2015

Your Hiring Managers; the value of converting Customers to Partners

May 1, 2017For decades, global manufacturing operations have leveraged Total Quality Management (TQM) programs and techniques to optimize their production and cost outcomes.

Through the use of these programs and techniques, leading manufacturing organizations have created the ability to identify where in their processes failures are occurring, and then, through the use of root cause analysis, identified why they are occurring.

By implementing changes required to eliminate these root causes of failure, manufacturing leaders have eliminated billions of dollars in costs of process quality from their manufacturing spend.

Recruitment and Manufacturing; two cumulative processes

Recruitment, like manufacturing, relies on a cumulative process model, where success in a series of process steps is required to achieve any degree of success in the overall process.

In cumulative process environments, success in any single process step doesn’t assure a positive overall outcome. Failure in any single process step, however, will, at a minimum, produce costs of process quality, and in the extreme, complete process failure.

This shared process characteristic makes recruiting enterprises a natural application opportunity for TQM, and its myriad of associated benefits.

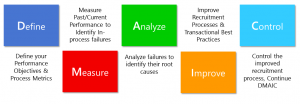

DMAIC: defining the path to continuous improvement

A standard TQM implementation uses a series of steps known by the acronym DMAIC.

TQM and the Recruitment Enterprise

Design of transactions

As in all DMAIC implementations, the Design of process transactions, as well as the tools and methods used to execute them, starts with the definition of the desired outcome.

For example, when designing a candidate pre-interview screening transaction, your desired outcome may be to invite in for interviews only candidates meeting minimal job requirements, who have no identifiable barriers to closure; no issues that would prevent them from accepting and starting employment in a timely manner.

If achieved, this outcome would eliminate the cost of interviewing candidates who are either unqualified, or unable to start in a timely manner.

Should that be your desired outcome, you would then identify the activity, or transaction, driving your achievement of the desired outcome. In this case, your challenge would likely be the design of a pre-screening methodology, defining who would perform pre-screening transactions, and the tools and methods they would use in the execution of their assigned duties.

Measuring transactional performance

Most, if not all, desired outcomes for the recruitment process can be tracked and quantified as a function of good record keeping within your organization’s Applicant Tracking System (ATS).

In the above example, where the desired outcome is to invite in for interviews only candidates meeting minimal job requirements, who have no identifiable barriers to closure, results against that outcome can be tracked, rolled up and analyzed using an interview feedback form, indicating why an interviewed candidate wasn’t offered a job.

As long as “didn’t meet minimum job requirements” and “unwilling or unable to accept conditions of employment” are included as reasons why the candidate was not offered a job, you can begin to gather the information required to analyze your organizations pre-screening transactional failures.

For additional information regarding the value of the use of Diagnostic, versus Performance Metrics for the identification of transactional failures, please refer to Diagnostic Metrics; Making Recruitment Quality Systems Impactful

Analyzing transactional failures

The analysis of transactional failures to determine their root causes involves resolving whether the failures were the result of a flawed transactional design, the use of inappropriate tools or methods of execution, or poor execution by specific teams or individual employees.

The first step in the effort is to determine if there are clusters of failures, where failures are occurring as a rate exceeding the norm for the enterprise. Most often, these clusters will occur in a specific job class or family, within a division, department or other subset of the organization, or with individual hiring managers or HR partners.

While you certainly want to eliminate the root causes of all transactional failures, when you can eliminate them in clusters, the return on your effort is most substantial.

When you do identify clusters, or individual instances of transactional failures, you must then meet with the people who performed the transactions to determine what factor produced the failures. Was it a faulty transactional design, a failure to use the proper tools or techniques, or a failure resulting from ineffective or inadequate training?

Once the root cause of the failure is identified and validated, you’re ready to move to the next step in the process.

Improving performance

Depending on the root cause of the transactional failures identified, you may choose to pursue one or more of the following options:

Improved process/transactional design: From time to time, an organization simply fails to figure out the best way to execute a business transaction, and pays the price in costs of process quality. Changes made on this front, however, can be very disruptive, so it’s important to only make them when the value of making the change is highly compelling, far outweighing its cost.

Improved tools or execution methods: You will sometimes discover that the tools and methods defined for a specific transaction need to be improved or updated. This is another type of change that can be very disruptive, though, if attempted as a singular event.

Desired changes to transactional design, tools, or execution methods should be introduced to the organization no more than once a year. An optimal review and change cycle for improvements of this nature is either 12 or 24 months; a cycle short enough to achieve significant benefits in the reduction of costs of process quality, but long enough that your hiring managers won’t begin to wonder about the competence level of their recruiting leadership.

Improved training in transactional knowledge, tools, and execution methods: Most transactional failures occur because some part of the organization hasn’t received the training required to successfully perform their assigned transactions.

As a result, you shouldn’t be surprised to find that the shortest, and least disruptive path to recruitment performance improvement lies in the design and delivery of transactional execution training to your hiring managers and their HR partners.

Control through continuous improvement

Process quality is a journey, not a destination, as the opportunity to improve performance constantly changes in its nature and form.

Through the use of regular, scheduled transactional performance reviews, leveraging the use of diagnostic metrics, and supported by root cause analysis (which could actually become a function of the organization’s Quality team), any organization can take the first step on the road to continuous improvement.

What’s the cost justification?

A company, regardless of size, administering 2,000 interviews (or roughly 500 hires) a year, is likely to cut more than $230,000* a year from its recruiting spend through the achievement of just a 5% improvement in transactional performance.

Since these cost models are scalable, you can estimate your annual savings opportunity by simply comparing the number of interviews your company is administering to the 2,000 interview baseline.

For example, if your company is administering 4,000 interviews (or roughly 1,000 hires) this year, the savings you can achieve from a 5% improvement in transactional performance would be estimated at more than $460,000*.

*These estimates don’t assign any value to soft costs, such as cycle time improvements; just the hard costs associated with interviewing and offer administration.

If your organization hires as few as 500 people a year, once you do the math, the savings opportunity, and resulting cost justification becomes a complete no-brainer.

Just ask any functional or finance executive working in your Manufacturing or Quality organization.